Produkti

-

-

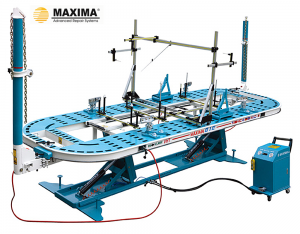

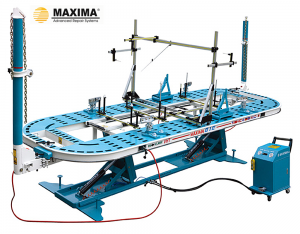

MAXIMA karstā izpārdošana jauna dizaina auto iespiedumu izvilkšanas sols B sērija, virsbūves remonta mašīna

2.1Pilna izmēra modelis – L sērija/ M sērija/ B sērija

-

MAXIMA karstā izpārdošana jauna dizaina auto iespiedumu izvilkšanas stenda karkasa remonta mašīna

2.1 Pilna izmēra modelis – L sērija/ M sērija/ B sērija Specifikācijas Modelis L2E L3E M1E M2E B1E B2E Platformas garums 5200 mm 5500 mm 5500 mm 6100 mm 6100 mm 6500 mm Platformas platums 2100 mm 23 mm 23 6 mm noliecams pacēlājs Noliecams pacēlājs un paralēlais pacēlājs Darba augstums 500mm 380 -1020mm Vilkšanas jauda 10 tonnas Darba diapazons 360 grādi Celtspēja 3500kgs Svars 2200kgs 2500kgs ... -

-

2016. gada kabeļu modelis — zemākā cena!!!

Automātiska problēmu novēršana un atkļūdošana

Samontēts gan ar hidraulisko atbalstu, gan ar mehānisko fiksatoru

Automātiskā izlīdzināšana nodrošina sinhronizāciju

Maksimālā līmeņa ierobežojuma slēdži nodrošina automātisku apstāšanos, kad tiek sasniegts maksimums.

Liela ietilpība: viena kolonna iztur 1,5 reizes lielāku drošības slodzes testu.

Pārslodzes aizsardzības ierīce novērš pārslodziPamatojoties uz pamata bezvadu modeli, MAXIMAirizstrādāja jaunās bezmaksas savienojuma funkcijas: visas kolonnas iridentisks;kolonnas ar vienādu ietilpību var brīvi grupēt kā komplektu jebkurā laikā, piemēram, 2-, 4-, 6-, 8-, vai līdz 16-kolonnu komplektu utt., izmantojot vienkāršus iestatījumus.

Modelis ML4022 ML6033 ML4030 ML6045 ML8060 ML4034 ML6051 Kolonnu skaits 4 6 4 6 8 4 6 Ietilpība kolonnā 5,5 tonnas 7,5 tonnas 8,5 tonnas Kopējā jauda 22 tonnas 33 tonnas 30 tonnas 45 tonnas 60 tonnas 34 tonnas 51 tonna Maks.pacelšanas augstums 1700 mm Pacelšanas/nolaišanas laiks 120./100. gadi Pacelšanas sistēma Hidrauliskais Enerģijas padeve 208V/220V 3 fāzes 60Hz;380V/400V/415V 3 fāzes 50Hz Motora jauda 2.2Kw uz kolonnu Svars 600 kg vienā kolonnā Izmērs 2300 mm (A) * 1100 mm (W) * 1300 mm (G) Darbība ir pieejama pie katras kolonnas un tālvadības pults roktura.

Slēdzis uz galvenās vadības bloka nodrošina vienas, dubultās vai visu kolonnu darbību.

Hidrauliskā elektriskā sistēma nodrošina drošu un ļoti precīzu reāllaika vadību.

Ar modernām tehnoloģijām SCM vadības sistēma nodrošina pacelšanas sinhronizāciju.

Dubultā drošības sistēma: mehāniskā bloķēšana un hidrauliskais pretvārsts.

Regulējams riteņu balsts atvieglo darbību.

Mobila un elastīga, sistēmu var izmantot iekštelpās vai ārā.

Ūdensnecaurlaidīgs dizains izmantošanai komerciālās mazgāšanas telpās.

Nepieciešama tikai plakana, stabila grīda un strāvas avots, bez uzstādīšanas izmaksām.

CE apstiprinātsRegulējami riteņu balsti, kas atbilst riteņu izmēriem no 380 līdz 1156 mm

)Kompanijas profils:

MIT Group, kas dibināta 1992. gadā, gadu gaitā ir koncentrējusies uz automobiļu pēcpārdošanas tirgiem un ir kļuvusi par nozares līderi, piegādājot mūsdienīgus produktus un pakalpojumus mūsu cienījamiem klientiem visā pasaulē.Grupas zīmoli ir MAXIMA, Bantam, Welion, ARS un 999.Kā MIT grupas meitasuzņēmums MAXIMA ir profesionāls automobiļu virsbūves remonta sistēmu un lieljaudas kolonnu pacēlāju ražotājs, kas gadu gaitā ieņēma 65% Ķīnas tirgus un piegādā 40 uzņēmumiem nozarē Ķīnā. + valstis ārzemēs.Ar lepnumu MAXIMA ir unikāls uzņēmums Ķīnā, kas var nodrošināt visprofesionālākos inovatīvos risinājumus, tehnisko attīstību, apmācību un klientu atbalstu auto virsbūves remontam un apkopei.Mēs ceram uz biznesa sadarbības veidošanu ar izplatītājiem un klientiem visā pasaulē.)

)

)

Kvalifikācijas un sertifikāti (ISO, CE, ALI sertificēts)

)

-

vairumtirdzniecība augstas kvalitātes Maxima FC75 ar kabeļiem Heavy Duty Column Lift 4 stabu autopacēlājs

Automātiska problēmu novēršana un atkļūdošana Samontēts gan ar hidraulisko atbalstu, gan mehānisko fiksatoru Automātiskā nivelēšana nodrošina sinhronizāciju Maksimālā robežslēdži nodrošina automātisku apstāšanos, sasniedzot maksimumu.Liela ietilpība: viena kolonna iztur 1,5 reizes lielāku drošības slodzes testu.Pārslodzes aizsardzības ierīce novērš pārslodzi Balstoties uz bezvadu pamata modeli, MAXIMA ir izstrādājuši jaunas bezmaksas savienojuma funkcijas: visas kolonnas ir identiskas;kolonnas ar vienādu ietilpību var brīvi grupēt kā kopu jebkurā laikā... -

vairumtirdzniecība augstas kvalitātes Maxima FC85 kabeļu Heavy Duty Column Lift 4 post autobusa lifts

Automātiska problēmu novēršana un atkļūdošana Samontēts gan ar hidraulisko atbalstu, gan mehānisko fiksatoru Automātiskā nivelēšana nodrošina sinhronizāciju Maksimālā robežslēdži nodrošina automātisku apstāšanos, sasniedzot maksimumu.Liela ietilpība: viena kolonna iztur 1,5 reizes lielāku drošības slodzes testu.Pārslodzes aizsardzības ierīce novērš pārslodzi Balstoties uz bezvadu pamata modeli, MAXIMA ir izstrādājuši jaunas bezmaksas savienojuma funkcijas: visas kolonnas ir identiskas;kolonnas ar vienādu ietilpību var brīvi grupēt kā kopu jebkurā laikā... -

vairumtirdzniecība augstas kvalitātes Maxima FC55 kabeļu Heavy Duty Column Lift 4 post autobusa lifts

Automātiska problēmu novēršana un atkļūdošana Samontēts gan ar hidraulisko atbalstu, gan mehānisko fiksatoru Automātiskā nivelēšana nodrošina sinhronizāciju Maksimālā robežslēdži nodrošina automātisku apstāšanos, sasniedzot maksimumu.Liela ietilpība: viena kolonna iztur 1,5 reizes lielāku drošības slodzes testu.Pārslodzes aizsardzības ierīce novērš pārslodzi Balstoties uz bezvadu pamata modeli, MAXIMA ir izstrādājuši jaunas bezmaksas savienojuma funkcijas: visas kolonnas ir identiskas;kolonnas ar vienādu ietilpību var brīvi grupēt kā kopu jebkurā laikā... -

Premium modelis – Maxima (ML4030WX) mobilais bezvadu pacēlājs, kravas pacēlājs, autobusu pacēlājs

Modelis ML4030WX Kolonnu skaits 4 Kolonnas ietilpība 7,5 tonnas Kopējā jauda 30 tonnas Maks.Pacelšanas augstums 1820 mm Pilna pacēluma laiks 90 sek Motora jauda 3Kw kolonnā Akumulatora ietilpība 20 augšup un lejup (Pilna uzlāde) Svars 710kgs uz kolonnu Kolonnas izmēri 2300mm(H)*1100mm(L)*1300mm(L) Izejas spriegums 24v līdzstrāva Spriegums lādētājam 110V/220V AC grupa Kolonnu skaits 2,4,6,……32 kolonnas Piezīme: automātiskās kustības funkcija nav obligāta.Pacēlājs ar automātu... -

Premium modelis – Maxima (ML4034WX) mobilais bezvadu pacēlājs, kravas pacēlājs, autobusu pacēlājs

Modelis ML4034WX Kolonnu skaits 4 Kolonnas ietilpība 8,5 tonnas Kopējā ietilpība 34 tonnas Maks.Pacelšanas augstums 1820 mm Pilna pacēluma laiks 90 sek Motora jauda 3Kw kolonnā Akumulatora ietilpība 20 augšup un lejup (Pilna uzlāde) Svars 800kgs uz kolonnu Kolonnas izmēri 2300mm(H)*1100mm(L) Izejas spriegums 24v DC Ieeja Spriegums lādētājam 110V/220V AC grupa Kolonnu skaits 2,4,6,……32 kolonnas Piezīme: automātiskās kustības funkcija nav obligāta.Pacēlājs ar automātu... -

Premium modelis – Maxima (ML4022WX) mobilais bezvadu pacēlājs, kravas pacēlājs, autobusu pacēlājs

Modelis ML4034WX Kolonnu skaits 4 Kolonnas ietilpība 8,5 tonnas Kopējā ietilpība 34 tonnas Maks.Pacelšanas augstums 1820 mm Pilna pacēluma laiks 90 sek Motora jauda 3Kw kolonnā Akumulatora ietilpība 20 augšup un lejup (Pilna uzlāde) Svars 800kgs uz kolonnu Kolonnas izmēri 2300mm(H)*1100mm(L) Izejas spriegums 24v DC Ieeja Spriegums lādētājam 110V/220V AC grupa Kolonnu skaits 2,4,6,……32 kolonnas Piezīme: automātiskās kustības funkcija nav obligāta.Pacēlājs ar automātu... -

M1000 automātiskās virsbūves izlīdzināšanas stends

Neatkarīga centralizēta vadības sistēma: viens rokturis var pacelt un nolaist platformu, vilkt torņus un sekundāro pacelšanu.Tas ir viegli darbināms un efektīvs.

Platforma var pacelties uz augšu un uz leju vertikāli un noliecama pacelšana noteiktā augstumā.Zemākajā pozīcijā ir viegli uzstādīt vai demontēt torņus, ko var veikt viens cilvēks.